In winter, domestic and industrial tanks, in the open air or located in an unheated room (in order to protect against freezing and maintain the required process temperature), need heating. TeploKhimMash specialists carry out calculations for the most efficient heating, selection of materials and complete set of automated electrical heating system. We carry out work on the installation of heating elements, гарантийному обслуживанию и ремонту.

Существует два способа обогрева резервуаров и ёмкостей:

- Обогрев с помощью греющих кабелей. Традиционный вид обогрева со свойственным набором недостатков.

- Обогрева резервуаров и емкостей при помощи гибких панелей типа RT (RT -2022, RT-1022, RT-522 , RTF-2260, RTF-2284).

Heating panels offer a number of advantages over conventional heating cable systems

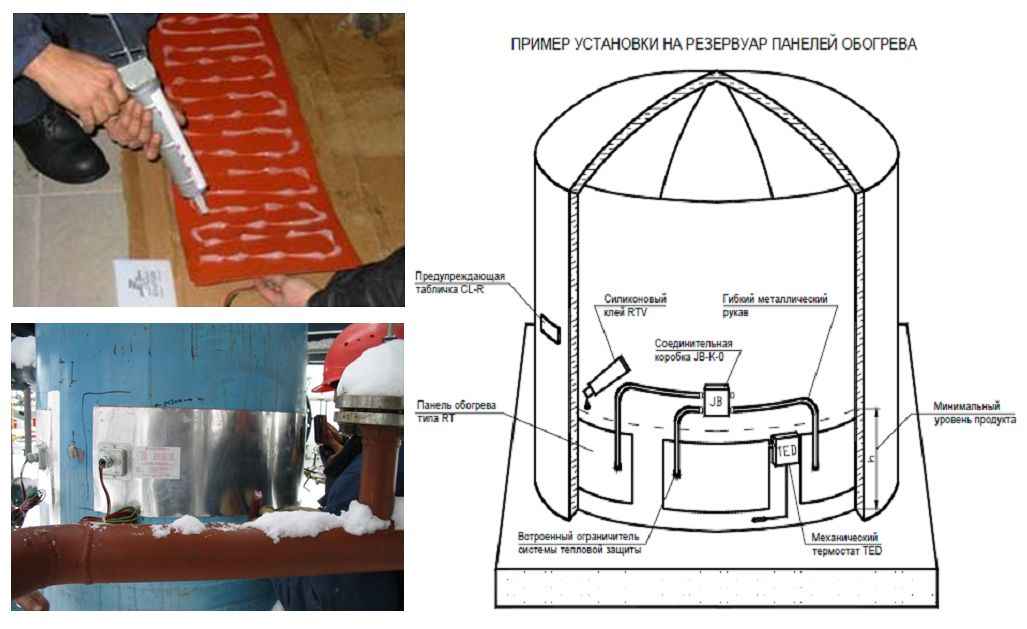

- Quick, простой и надежный монтаж путем приклеивания нагревательной панели на силиконовый клей к резервуару (Minimum installation temperature - 55 0FROM);

- Максимальная площадь контакта панели и обогреваемой поверхности -позволяющая увеличить эффективность системы обогрева.В отличие от кабельных систем обогрева, heating panel, thanks to its design, has a reliable 100% contact with heated surface, which increases the efficiency of heat transfer to the walls of the tank;

- Minimum area, occupied by the tank heating system, due to high power density compared to cables. This allows you to significantly reduce the size of the heating system and place them compactly in the lower part of the tank, instead of wrapping the entire tank with the cable.

- Compact panel placement - usually, panels are placed below the minimum possible level of the product and really heat the product, а не пустое пространство резервуара.

- Easy troubleshooting- local location of panels under insulation. It is difficult to determine the location of the cable damage on the tank under thermal insulation.. Panel is easy to change, and to replace the cable, you will have to remove the insulation from the entire tank.

- High reliability - the heating element uses parallel circuits, based on forged high temperature alloy heating elements (this design eliminates the possibility of burnout, as opposed to sequential circuits).

- Стойкость к высоким температурам – температура непрерывного воздействия составляет 232 0FROM.

- Встроенный ограничитель температуры в каждой панели - protect the panel and product from overheating, обеспечит индивидуальную чувствительность к температурным режимам каждой панели обогрева, not just systems as a whole..

- Vibration and humidity protection - the heating element is laminated in a layer of silicone rubber

Скачать: